This was harder than I expected.

- Part 1: resistive sensing

- Part 2: finding resistive sensing is bad and capacitive sensing is hard

- Part 3: another crack at a capacitive sensor

- Part 4: calibrating the sensor

Day III (weekend 3)

Not really much time this weekend. I pulled out the electrode and (it had been sitting there unpowered) and saw this:

Copper salts deposited on the electrodes. It was really hard to get my phone to reproduce the colour.

It looks like corrosion has already started. There’s not much but it’s only been there a few weeks and has probably spent a few of hours powered by now. With my current plan (maybe waking up every 30 minutes), the amount of time ‘on’ would be about 16 minutes per day (10 seconds of higher current charge in each direction). That’s only a week or two before it reaches these levels of corrosion. So, that I think precludes 10 second measurements, or at least 10 seconds of direct charging without a resistor in the way.

Day IV (Weekend 4)

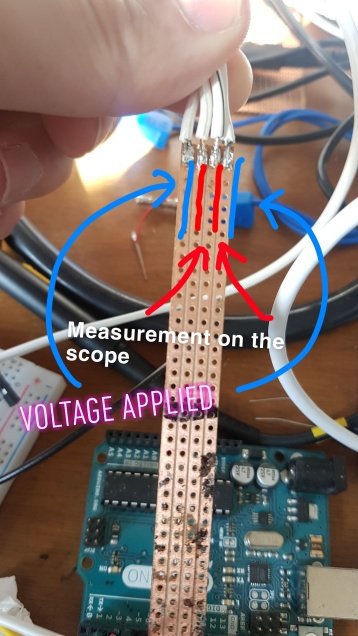

Wow really not getting as much time on this as I’d like. So, what about capacitive measurements? Having insulated electrodes should preclude any corrosion problems and I’ll bet that using soil as dielectric will increase the capacitance as the water content increases. First, an initial experiment:

The sensor is a bit of electrical tape over some strip board.

This indicates we’re into the realms of possibility, though the number of picofarads is still small enough to be pretty irritating. It’s also a pretty useless soil sensor: soil/water get through the holes behind and the result is a measurable resistance between the electrodes (about 9M or so). And the insulator is pretty thick which is going to make the capacitance low and reduce the sensitivity.

I do have some enameled wire in various grades. The finest (0.14mm) has a very thin coating. I made a couple of different sensors using the wire, mostly wrapping it around lots to get a decent surface area:

A couple of attempts at a capacitive sensor. Left, interleaved wires, right the two plates are well separated.

One slight problem: it doesn’t measure open circuit; there’s about 15M between the two sides, rising as it dries off. The flat one measures about 28pF when in the air, and about 280 in damp soil, rising to about 2nF when just watered. Unfortunately I don’t know how much the resistance is affecting this, so I’m going to have to try again. I’m going to try the next thicker grade of wire I have (0.23mm) and incidentally it has a different color coating.

Having a nice large spacing between the two plates seemed to work well in that it was easy to clean and reset back to the dry state. So, on to version 2:

Version two of the sensor with thicker wire and nicely soldered joints. 40 turns of wire in each section.

As a reminiscent aside, I remember soldering lacquered wire back in the olden days with my fixed temperature iron. I could never settle on fine sandpaper versus a flame to remove it. Those days I do not miss, now I just crank up the iron temperature.

Anyway this seems to be going better: the resistance is greater than 2G. I think I might have mentioned it before but my multimeter skipped leg day. It can measure up to 2GOhm, but only down to 20mA. Weird. On to the capacitance measurements. So they are:

- BOGUS! that’s what they are, bogus!

Well shoot. It seemed to be working great, but after a bit of use the resistance is back to being about 10M. That’s disappointing. OK, try3! I’m going to wrap the wires longitudinally so that they never even cross:

I forgot to take a picture of it! Look at the “fix” below with hot-melt to get the idea.

Anyway the wires are always separated by about 4mm. So the measurements are:

- First use: 12pF

- Finger lightly on one side: 28pF

- Fingers pressed on both sides: 100pF

- Damp soil: 185pf, 233pF, 202pF, 190pF

- Slightly compacted damp soil: 323pF,

- Same place during watering: 680pF

- Resistance: 12M

OK well, this is getting suspicious. The 20M range is maxed out. But the 2G range reads low (there’s nothing in between, that’s only a few % difference). Now the capacitance reads in the nF range as well. Hitting it with a heat gun seems to reset everything.

So putting a blob of water on in the middle doesn’t do anything. Butting a blob of water on the end where the wires are bent round quickly drops the resistance back town to 10M. I think the act of wrapping the wire breaks the insulation very slightly. Well, that’s irritating. Let’s see:

If you use hot melt and don’t have a reflow style hot air gun, you’re really missing out.

OK, so the new measurements:

- Damp soil: 250pF, 360pF

- During watering: 1nF

- After watering: 600pF and dropping

- Resistance: 𝟚𝟘𝕄

Apparently there is something hot-melt can’t fix. Observing more, the resistance is climbing very slowly, up to 26 now, now 40. Well, it might not matter. If I keep my measurement resistors well under the 20M range (say 200k), then the small error incurred due to leakage won’t matter. Still, I’d prefer to have it work properly.

So where are we? The capacitance sensor definitely works after a fashion, but we need to measure it. It bottoms out at 30pF, and is well into useful readings at about 300pF or so. I think I could get away with a 1M resistor safely. For an RC circuit, that would give a time constant of about 30us, which is small, but that’s at the 0 end of the range. It’s just about measurable on an Attiny85 with the 16MHz clock.

Additionally, the Attiny85 has a built in comparator. So, my current mental design has a relaxation oscillator in mind: charge up the capacitor through a 1M resistor, then discharge through a GPIO pin once the voltage crosses a threshold.

Sounds like a plan.